A Comprehensive Overview of PTFE and Its Versatility in Modern-Day Applications

Polytetrafluoroethylene (PTFE) is a synthetic polymer that has gained popularity in various industries due to its exceptional chemical resistance and non-stick properties. This material is a high-performance plastic that can withstand extreme temperatures, making it a reliable choice for various applications. In this article, we'll take a closer look at where PTFE is used and its many benefits in different industries.

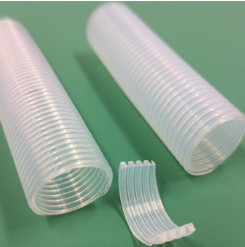

Industrial Applications

PTFE is widely used in industrial applications such as chemical processing, oil and gas, and semiconductor manufacturing. Its chemical resistance and non-stick properties make it an ideal material for lining tanks, pipes, and fittings that are exposed to corrosive substances. PTFE is also used in bearings, seals, and gaskets due to its ability to withstand high temperatures and pressure.

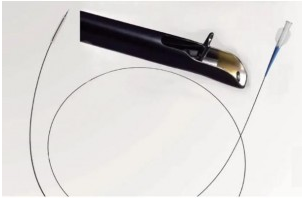

Medical Applications

PTFE is commonly used in the medical industry due to its biocompatibility and non-reactivity with human tissue. It is used in medical implants, such as cardiovascular grafts and artificial joints, as it is non-toxic and does not cause an immune response. PTFE is also used in catheters and other medical devices due to its non-stick properties, which reduce the risk of blood clots and infections.

Electrical and Electronics Industry

PTFE is an excellent electrical insulator, making it a popular material for electrical and electronic components. It is commonly used in wire and cable insulation, printed circuit boards, and other electrical equipment that requires a high level of insulation. PTFE's resistance to heat and chemicals also makes it a popular choice in battery and capacitor applications.

In conclusion, PTFE is a highly versatile material that is used in various industries due to its exceptional chemical resistance, non-stick properties, and ability to withstand extreme temperatures. From industrial applications to the food and beverage industry, medical applications, aerospace and automotive industries, and electrical and electronics industry, PTFE has become an essential material for various applications. With its unique properties and versatility, PTFE will continue to play a vital role in modern-day applications.

Aerospace and Automotive Industry

PTFE's unique properties make it a popular choice in the aerospace and automotive industries. Its low friction coefficient makes it ideal for use in bearings, gears, and other moving parts that require high performance and low wear. PTFE is also used as a coating material for aircraft and automotive parts to protect them from wear and corrosion.

Food and Beverage Industry

In the food and beverage industry, PTFE is used in manufacturing food-grade machinery and equipment such as conveyor belts, hoses, and seals. Due to its non-stick properties, PTFE prevents food particles from sticking to the equipment, making it easy to clean and maintain high hygiene standards. PTFE is also used in cookware coatings as a non-stick surface.

Post time: Mar-02-2023